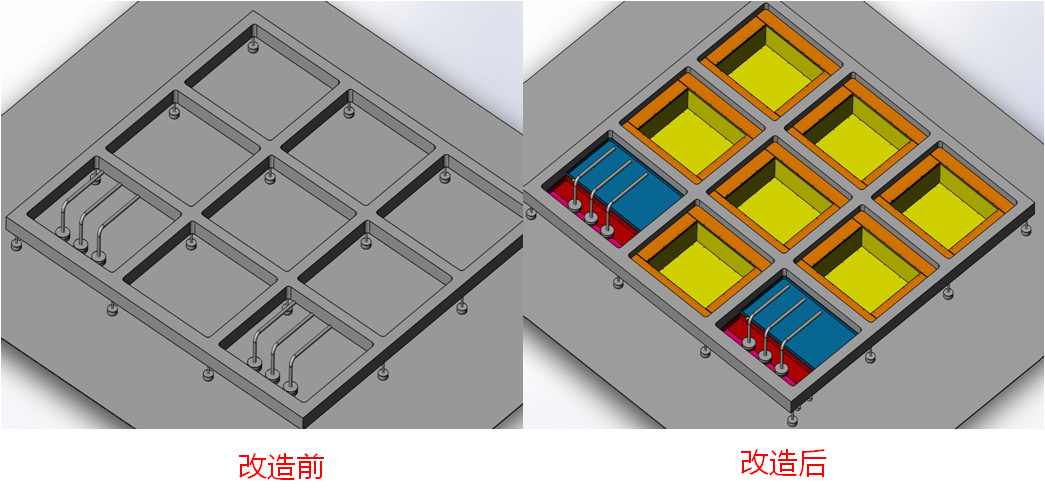

Reasons for transformation:

There are a large number of PCW pipelines under the CP Unit. Due to the long time, some pipeline interfaces are subject to high pressure, and there is a risk of loose leakage causing leakage; once a leakage occurs, there is no leakage device under the equipment, and the liquid can be directly The holes flow to Subfab; Subfab has a large number of electrical control cabinets and high-voltage cables. Once it encounters water, the consequences will be serious. It is now evaluated to install a leak box device under the CP Unit to avoid liquid outflow.

Transformation plan:

Install a leak-proof box between the frames below the equipment. The part of the leak-proof box without pipelines is of integral type; the part of the leak-proof box with pipelines is of spliced type. The spliced place seals and wraps the pipeline.

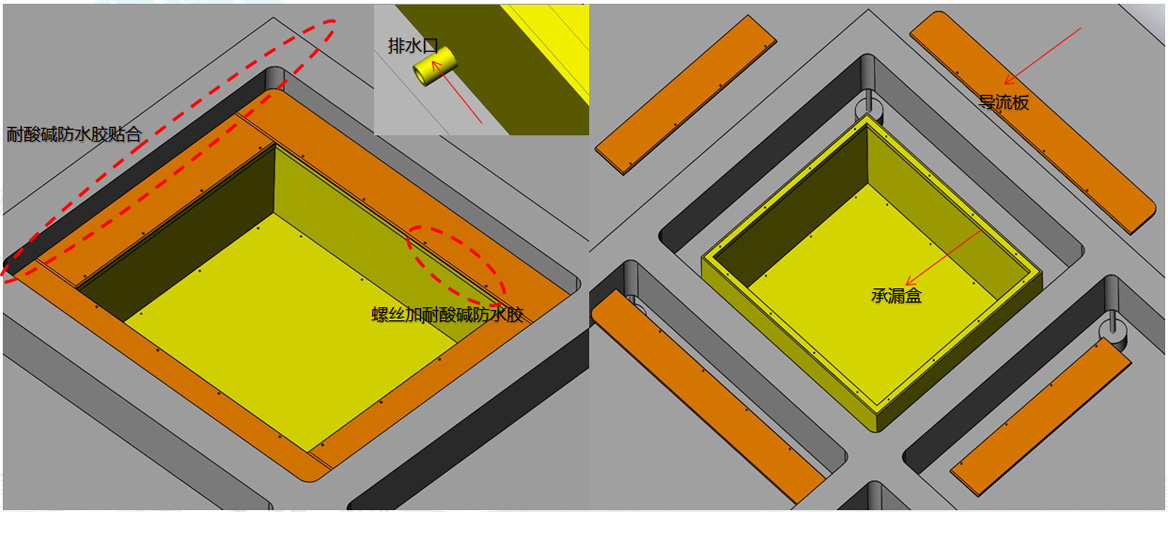

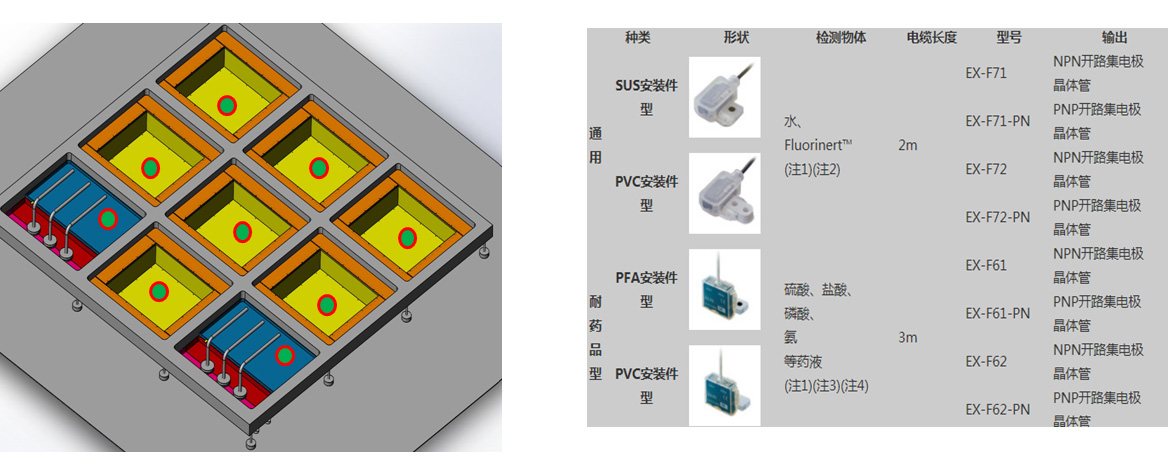

Effect picture of splicing leak-proof box:

Due to the interference of the pipeline, the leakage box under the pipeline is spliced, and the pipeline is sealed and wrapped at the splicing place, and bonded with acid and alkali waterproof glue; the machine frame is connected to the leakage box with acid and alkali waterproof glue Each drain box is equipped with a drain and connected with the drain of the other integral leak box in parallel to the factory drain.

Effect diagram of integral leak-proof box:

The machine frame and the deflector are bonded with acid and alkali-resistant waterproof glue; the deflector and the leak box are connected with screws and waterproof glue; each leak box is equipped with a drain and drained from other leak boxes After parallel connection, connect to the factory drainage pipe.

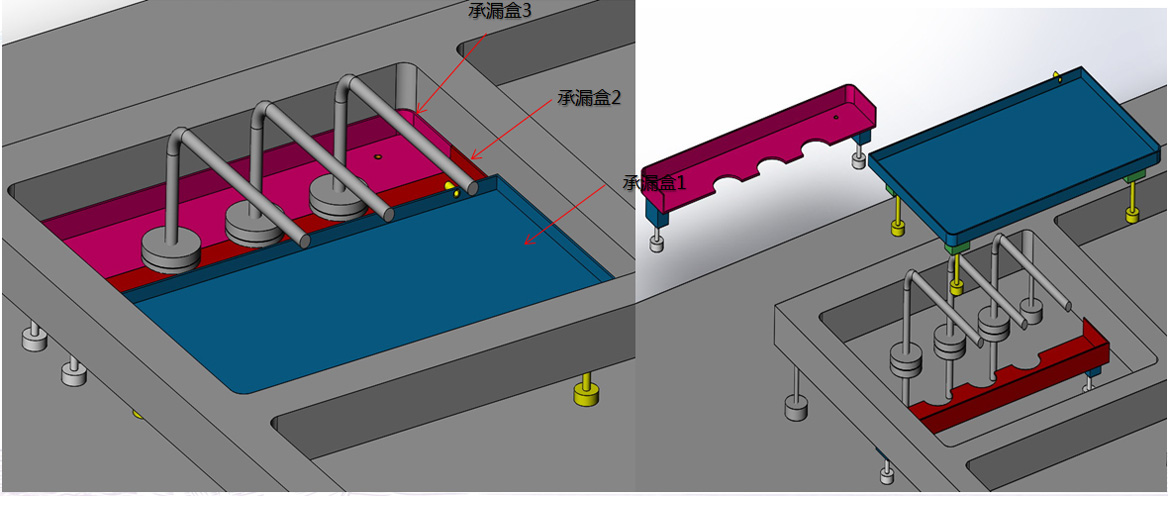

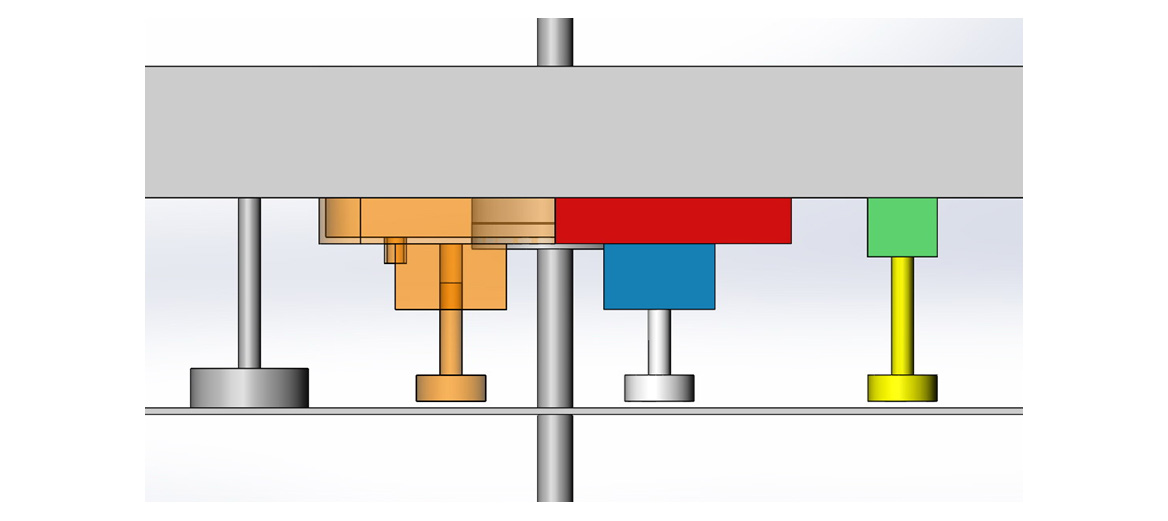

The rendering of the bottom of the leak box:

The bottom of each leak box can be adjusted in height

alarm system:

Each leak detection box is equipped with a liquid detection sensor, model: SUNX EX-F61 (specified by the customer); parallel with the liquid detection sensor of other Unit of the equipment. If the leakage occurs, the sensor will act, the machine will report "LEAK ALAM", and the power unit will stop immediately.

Shenzhen Xinyihang Technology Co., Ltd.

Contact: Mr. Ding

Telephone: 13048917302

Email: consin.feng@xinyhtech.com

Company address: Room 302, Building 1, Guole Technology Park, No. 1, Lirong Road, Dalang Street, Longhua District, Shenzhen